The most commonly used robot configurations are articulated robots, SCARA robots, Delta robots, and Cartesian coordinate robots (also known as gantry robots or x-y-z robots). Typical applications of robots include welding, painting, assembly, pick and place (such as packaging, palletizing, and surface mount technology), product inspection, and testing all accomplished with high endurance, speed, and precision. The most active industry in the application of robots is the automobile industry, and there is great interest in applying robots to weld and assembly operations, and to material handling. The demand for the use of robots stems from the potential for flexible, intelligent machines that can perform tasks in a repetitive manner at acceptable cost and quality levels.

Industrial robots are essential components of today's factory, and even more of the factory of the future.

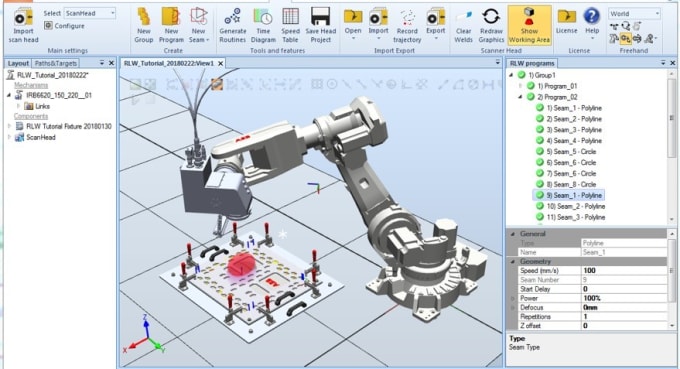

The use of robots is also highly desirable in hazardous manufacturing operations such as spray painting, and welding that pose known health risks to human operators. Robots have been successful in automating simple and repetitive operations while simultaneously enhancing the quality of manufactured products in many production areas. In this context, robots have played an important role in the automation of various operations. In this respect, CIM can be viewed as a closed loop control system where a typical input is the order for a product and the corresponding output is the delivery of the finished product ( 5).Īutomation of the physical production processes on the shop floor is a key component of the CIM strategy for improving productivity. The CIM strategy is to integrate the information bases of the various units of automation within the conventional framework of manufacturing. To this effect, the concept of computer integrated manufacturing (CIM) has been introduced in various production environments with different purposes, including human productivity improvement, product quality improvement, capital resource productivity improvement, and provision of rapid response to market demands. In today’s global marketplace, manufacturing organizations are facing national as well as international competition, forcing them to further improve their performances.

Khaksar, in Comprehensive Materials Processing, 2014 6.04.1.2 Industrial Automation

0 kommentar(er)

0 kommentar(er)